Fuel and boiler laboratory

Actions are being carried out to build a boiler-fuel laboratory, which is one of the stations of the CHP micropower plant, and which will be an integral part of it, such as tanks for various types of biomass, biomass transport system, boiler, gas reactor and exhaust aftertreatment system. Their work will be supervised by a measuring system that records, among others, temperature, pressure, humidity, streams, fuel parameters for combustion and heat loss to the environment. However, it will not be a traditional boiler, it is intended to be a low-power multi-fuel unit with diathermic oil with a maximum temperature of up to 350°C, which requires an appropriate flow meter (for turbine flow meters it should be special versions). However, the gas-gasification reactor, even though it is an increasingly common device in laboratories, creates additional measurement difficulties, such as the difficult measurement of the flow and temperature of the generated generator gas, resulting from both temperature and variation in composition of this medium. Additionally, this laboratory will be equipped with LDA and PIV sets to measure the speed fields inside these devices.

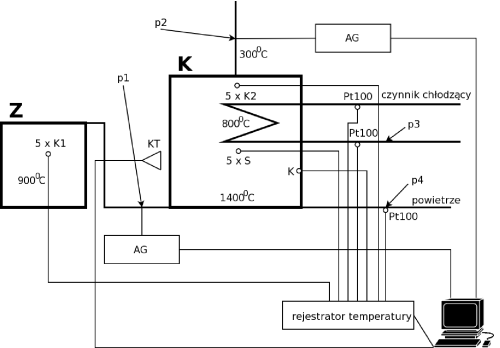

Diagram of the boiler-oil stand: K - boiler, Z - gas tanker, AG - gas analyser, KT - thermal camera, pand - flow meters, S - heat pumps type S, Kand - K-type, Pt100 thermoresistor.