Biofuels and Microenergy Laboratory

The Biofuels and Microenergy Laboratory is created at the Institute of Flow Machines of the Polish Academy of Sciences in Gdańsk, built as part of a project implemented by Pomeranian Special Economic Zone Sp. z o.o. (PSSE) and Provincial Fund for Environmental Protection (WFÓW). Construction started in the fourth quarter of 2011 and completed on 30 March 2012. At the same time, since the beginning of 2012, work has been underway on the design and execution of research installations and the purchase of measuring equipment and equipment.

The laboratory equipped with high-quality research equipment not only allows verification of new modern technological solutions, but it is an excellent place to exchange ideas and experiences and disseminate and stimulate the development of distributed cogeneration based on renewable energy sources in Northern Poland.

The laboratory shall consist of:

Biofuel position – high temperature gas and high temperature reactor installation for research of physicochemical processes accompanying thermal treatment of biomass and bio-based waste.

Figure 1. Continuous pyrolysis reactor

Figure 2. High temperature reactor with control console

Environmental combustion - the installation of a boiler with a universal design, enabling testing of heat-flow parameters in different configurations. Creates the possibility of conducting tests, e.g. in agreement with small boilers, burners, heat exchangers, etc.

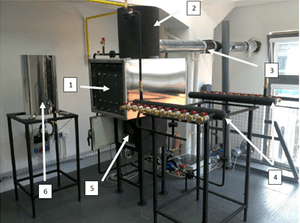

Figure 3. Multitasking laboratory boiler station: 1 - test chamber, 2 - discharge exhaust-water heat exchanger, 3 - tip with exhaust and flow-measurers, 4 - divider and water stream collector, 5 - combustion chamber

Heat exchange station - includes, inter alia, a fan cold store which operates all laboratory thermal and flow installations, i.e. the ecological combustion station, the gasification installation and the microenergy station. It is used for research on heat exchange issues in small energy installations.

Microenergy position – mainly includes combined heat and electricity production installations based on generated syngas. It allows testing and analysis of the efficiency of cogeneration systems based on gaseous fuel, derived from thermochemical treatment, e.g. gasification and pyrolysis, solid fuel (e.g. biomass, biodegradable waste).

The laboratory is equipped with high-quality research and measurement equipment, purchased from the PSSE and WFUŚ funds, as well as from the resources of various research projects carried out by IMP PAN. These include:

- NICON microscope

- UV-VIS spectrophotometer

- ASA Analyser

- Titrator Karl Fischer V20/C20

- Elemental analyser

- Thermal camera up to 2000°C

- System Particle Image Velocimeters (PIV)

Figure 4. PIV flow test station: 1 - Double laser Nd:Yag , 2 - control unit, 3 - CCD 1, 4 - CCD 2, 5 - seed generator (solid particles), 6 - oil-free compressor for continuous operation, 7 - acquisition system

- Calorimeter

- pHmeter

- Calibration furnace with temperature range 150 – 1200°C

- Resistance furnace

- Dryer, weight dryer, distiller, mill

- Temperature, pressure and flow rate sensors

- Heat exchangers (tube, plate, tube type, spiral) with fittings

- WD-XRF spectrometer

- GCMS chromatograph

- GC FID-TCD chromatograph

- Ion chromatograph

- Liquid chromatograph

- FTIR spectrometer

- Differentiating scanning calorimeter

- SDT thermometer

Figure 5. Chemical Analysis Position

For more details see: http://lbim.gpnt.pl/.

| |

|

|