Poligeneration ORC system

The system is a model of professional poligeneration unit for the production of electric energy, heat and cold for power range 0.1 – 1MWe. It utilizes available medium-temperature heat (at about 350oC). The system contains:

- gas boiler of power 500 kW,

- ORC unit working with MDM of power 80 kWe with an axial multi-stage turbine and radial single-stage turbine,

- connection to electric grid,

- heating instalation,

- system for production of cold of power 20 kW.

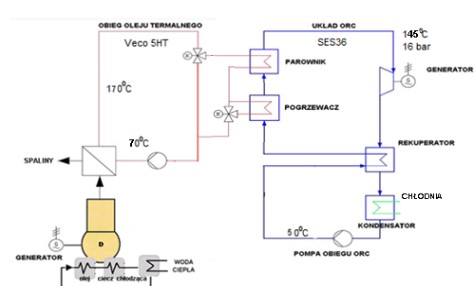

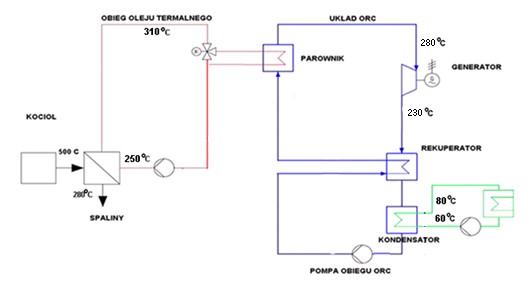

Schematic of the 80 kWe ORC system

Main ORC parameters:

- turbine - from 12 bar/280oC to 0.17 bar/230oC,

- recuperator – vapour 230oC/130oC, liquid 90oC/190oC,

- evaporator – 280oC,

- condenser – 90oC,

- hot water – 80oC/60oC.

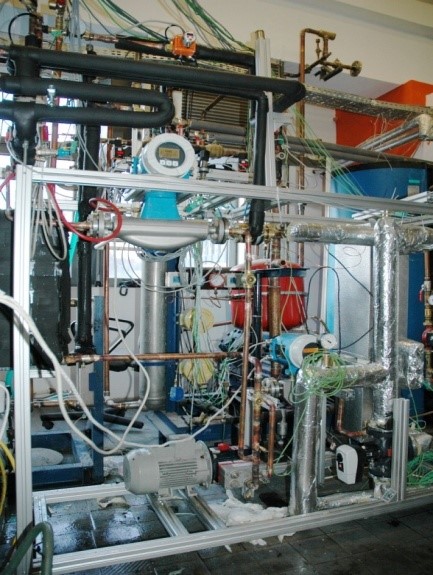

ORC installation

Gas boiler for heating thermal oil

- hybrid bearings lubricated by oil,

- multistage axial turbine of 9 000 rev/min,

- partial admission,

Gas-vapour ORC system

The installation is a container system for cogeneration of electric energy and heat with a high efficiency of electric energy production. The main unit is a gas combustion piston engine. Another unit is an ORC unit that utilizes the heat of exhaust gases from the engine. The system cointains:

- piston engine of MAN of power 380 kWe,

- heat recovery boiler of 280 kW,

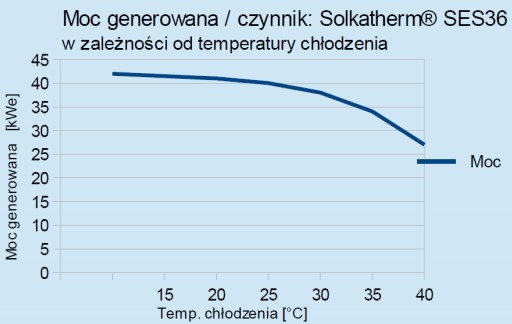

- ORC unit working with SES36 with two pneumatic engines with rotating pistons and alternatively a radial-axial single-stage turbine of power 40 kWe,

- connection to electric grid,

- heating installation.

Parameters of 12 cylinder piston engine:

- Electric power - max 420 kWe,

- Heat power in exhaust gases - 280 kW,

- Heat power from engine cooling - 230 kW,

- Electric efficiency for natural gas - 40% el.

Parameters of the ORC unit:

- Brut electric power: 40 kWe

- Heat source: thermal oil Veco 5HT, heat power 280 kW, temperatures inlet/outlet: 170oC/110oC

- Cooling: 40% glycol, cooling power 265 kW, temperatures inlet/outlet: 35oC/55oC

Expander

- Pneumatic engine with rotating engines in a hermetic capsule,

- 1500 rpm,

- Ball bearings with membrane lubricated by injection of oil.

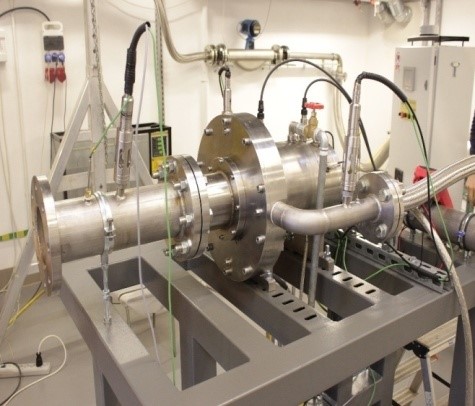

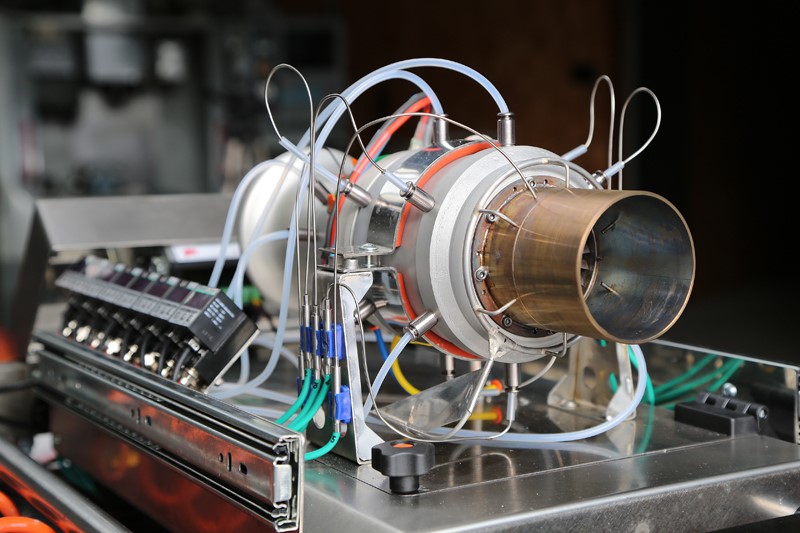

Radial-axial turbine with a high rotating generator of 40 kWe

- mass – 1,162 kg/s,

- pressure drop from 14.64 to 2.20 bara,

- rotational velocity – 15000 rev/min.

Combustion piston engines facility

The facility serves for investigation of combustion of low caloric gases from gasification of biomass in piston engines. The facility includes:

- installation of combustion pistom engines - CEZ of power 60 kWe supplied by syngaz and PERKINS of power 30 kWe supplied by biogas,

- station for mixing of technical gases,

- supply system,

- system AVL for engine indication.

Biogas turbine facility

Software

- CAD (computer aided design) software TURBINA and SimAx based on 0/1D model for calculation and design of turbine flow systems of axial, radial, radial-axial turbines,

- AGILE (AXIAL, RITAL) software for design of turbine flow systems of axial and radial turbines,

- 3D RANS solvers for investigations of gas flow in turbomachinery - Fluent, CFX (ANSYS) and FlowER (Yershov, Rusanov),

- CSM (computational structure mechanics) software – ANSYS and solver solwer WYKA based on finite elements of shells of medium thickness,

- Optimisation packages such as Opti_turb for interdisciplinary efficiency optimisation of turbomachinery blading systems.